Products

Contact us

Phone:+86-18862868880

Tel:+86-513-82577173

E-mail:sun@tcfjcn.com

Add:Room 406-1, IN International Qingchuang Community, No.501 Qingnian Middle Road, Xianfeng Street, Tongzhou District, Nantong City

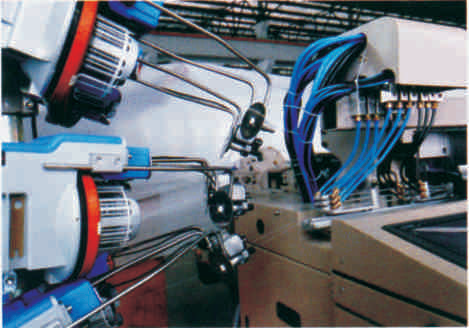

ZY600 Series High Speed Air Jet Loom

The company's business scope includes the sales of textile machinery and accessories, textile auxiliary equipment and accessories, textiles, textile fabrics, complete sets of electrical control systems for textile equipment, electrical equipment, rubber and plastic products, chemical products and raw materials (except dangerous goods).

Keywords:

Textile Machinery | Textile Machinery Accessories | Textile Equipment

Category:

Hotline:

Product details

Textile machinery is all kinds of mechanical equipment needed to process natural fiber or chemical fiber into textiles. Although the machinery for producing chemical fibers includes various chemical machinery, it is now considered an extension of textile machinery and belongs to the broad category of textile machinery. The processes required to process different fibers such as cotton, linen, silk, and wool into textiles vary, some of which are completely different, resulting in a wide variety of machines required. Textile machinery is usually classified according to production processes, including spinning equipment, weaving equipment, printing and dyeing equipment, finishing equipment, chemical fiber drawing equipment, silk reeling equipment, and nonwoven fabric equipment. Spinning equipment is divided into two categories: processing short fibers and processing long fibers. Cotton and cotton type chemical fibers belong to the short fiber category, while wool, linen, silk, and their blended chemical fibers belong to the long fiber category. The processing procedures for the two types of fibers are different, and the equipment cannot be interchangeable, except that the design principles of some machines are similar. Even if the structure of the same type of equipment is similar to that of the machine, it is generally not universal due to the different properties of the raw materials and the requirements for the fabric.

Textile machinery is the production method and material foundation of the textile industry, and its technical level, quality, and manufacturing cost are directly related to the development of the textile industry.

The double swing main spray device adopts the swing type series booster main nozzle, so that the air flow sprayed from the nozzle has a more gentle effect on the weft yarn, and further improves the performance of the machine.

Main features

The ZY600 air-jet loom adopts a box-type wall panel structure with reasonable structure and strong stability, and a multi-support counterweight balance weft beating system, which makes the loom more stable when running at high speed and more conducive to tightening the weft. Equipped with high-speed response imported solenoid valve, optimized gas path control system, using the most advanced Toyota 810 fixed main nozzle + swing main nozzle + auxiliary nozzle high-speed weft insertion mode, so that the loom gas 35%. Electronic let-off, electronic coiling, mechanical let-off, mechanical coiling, in order to meet different customers to provide a variety of solutions, the opening form not only has a lower jet cam, multi-arm, can also use the upper spray faucet, more economical. The various designs of the rear beam seat can meet the adjustment of the position line of various raw materials such as chemical fiber, pure cotton and blended spinning, which expands the weaving range of the loom. It is the best model to replace water jet loom and rapier loom.

Related products

Message

Nantong Tianchang Textile Machinery Co., Ltd.

天畅纺织

Tel: +86-18862868880

Tel: +86-513-82577173

E-mail: sun@tcfjcn.com

Address: Building 2-24190, No. 5 Xindong Road, Nantong Development Zone

Mobile website

Copyright © Nantong Tianchang Textile Machinery Co., Ltd. All rights reserved